Ram Heavy Duty Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Articulink? Technical discussion

- Thread starter el_barto

- Start date

Rockcrawlindude

a rock crawlin’ dude

That’s ok I don’t mine starting one for you.That was kind of my thought but I didn't want to start an argument.... lol.

UglyViking

Well-Known Member

- Joined

- Jul 11, 2020

- Messages

- 1,309

- Reaction score

- 1,599

That's something I've been thinking about for a while. I know Carli uses these joints on their radius arms, vs the OEM vulcanized rubber that Thuren uses on his. I think the primary question between the two is are you willing to trade maintenance requirements for articulation?That joint will allow more vibrations to the chassis and will have a significantly shorter service interval than the vulcanized rubber joint’s service life. It will allow more flex and it is serviceable but overall I think it’s a downgrade.

I've never had radius arms with these joints but you think there is that much chassis vibration coming through?

Crusty old shellback

Well-Known Member

- Joined

- Apr 10, 2021

- Messages

- 2,951

- Reaction score

- 4,581

Regular 2500 is stiffest. PW is in the middle. Thuren is the softest. Got that straight from Thuren.Of course rear coil spring rate comes into play. Anybody know how the spring rate compares between PW and non-PW 2500s with gas engines?

Trail_Wagon

Well-Known Member

- Joined

- Dec 3, 2021

- Messages

- 254

- Reaction score

- 603

UglyViking

Well-Known Member

- Joined

- Jul 11, 2020

- Messages

- 1,309

- Reaction score

- 1,599

I do wonder why not just do a 4 link at that point? Like, even with all this additional flex, a 4 link is still going to flex more right? Perhaps this is right in that sweet spot?

Darkone

Well-Known Member

A 4 link would add more work, this was a relatively easy modification. As far as benefit for amount of work, Im not familiar enough with those joints to say. I will say the vibrations that could be transmitted back into the frame couldn’t be as bad as what my current transforce tires send back.

Rockcrawlindude

a rock crawlin’ dude

I do like the ability to push the axle forward a little with this modification. I need 1/2”Looks like he finished up. I think it's one of the new 3.0 Johnny joints at the frame. Bung is welded in nice. Pretty slick for very little money.

Johnny joints don't transfer vibration to the cab. That's marketing BS. They also require nearly no maintenance.

View attachment 39154

View attachment 39155

Rockcrawlindude

a rock crawlin’ dude

Oh please tell me more about the things I can’t do. I especially want to hear how I’d mess up my shocks.no you can't........well you could but you'll fk your shocks up and your springs won't sit right.

Well the shock is hard mounted at the top and isn’t meant to articulate forward and rearward. I’m sure the springs could handle the movement. Not sure the shocks would like it. I mean i could be wrong.Oh please tell me more about the things I can’t do. I especially want to hear how I’d mess up my shocks.

Trail_Wagon

Well-Known Member

- Joined

- Dec 3, 2021

- Messages

- 254

- Reaction score

- 603

The top of the shocks is basically a bolt that goes through two rubber isolators. Remember shocks don't hold up anything, only dampen oscillation. They wouldn't be the least but bothered by the axle being moved 1/2. Springs don't care either, although it might cause them to bow slightly.

Actuall areas of concern would be steering. You don't want drag links, track bars, and diff covers trying to share the same space... But 1/2 is probably in the realm of okay.

Actuall areas of concern would be steering. You don't want drag links, track bars, and diff covers trying to share the same space... But 1/2 is probably in the realm of okay.

Rockcrawlindude

a rock crawlin’ dude

you are. Lol.I mean i could be wrong.

When you lift the truck, the radius arm effectively becomes shorter. It needs a little more length to be correct. I’d like to get that length without a drop crossmember relocating it

Think of the front suspension as a triangle. The distance between the top coil bucket and the frame mount of the radius arm is one length. The distance of the radius arm is the second length. The distance between the two coil buckets is the third length. If you change the length/height of the coil without lengthening the radius arm you get a tire that isn’t centered in the wheel arch.

Last edited:

Darkone

Well-Known Member

I would think the 1/2” might help with re centering your axle after leveling/lifting. Wasn’t that kinda the rule of thumb with 3rd gens after a leveling kit to really center everything was 1/2” long control arms. I know the suspensions are different long arm/short arm vs radius arm but I feel the concept is the same.

Lifting the suspension but keeping the radius arm/ links the same pulls the axle back, even if it’s just slightly. Everyone combats this by adjusting their caster but this seems to be a simple fix to that.

Now I’m no engineer nor do I have much background in building or racing suspensions, so if I’m missing something let me know.

Lifting the suspension but keeping the radius arm/ links the same pulls the axle back, even if it’s just slightly. Everyone combats this by adjusting their caster but this seems to be a simple fix to that.

Now I’m no engineer nor do I have much background in building or racing suspensions, so if I’m missing something let me know.

loveracing1988

Well-Known Member

- Joined

- Feb 16, 2021

- Messages

- 387

- Reaction score

- 285

I'd again request SOMEONE try this kit out because I don't want to be a guinea pig... It could definably help out your being too short problem...you are. Lol.

When you lift the truck, the radius arm effectively becomes shorter. It needs a little more length to be correct. I’d like to get that length without a drop crossmember relocating it

Think of the front suspension as a triangle. The distance between the top coil bucket and the frame mount of the radius arm is one length. The distance of the radius arm is the second length. The distance between the two coil buckets is the third length. If you change the length/height of the coil without lengthening the radius arm you get a tire that isn’t centered in the wheel arch.

14-C Gen Ram bolt-on Adjustable Radius Arm

‘13/14 to Current Ram 2500/3500 Adjustable Radius Arm kit. Replaces your original radius arm with a much stronger and better looking part that is able to be adjusted to match your custom vehicle ride height. No modifications are required to fit these to your truck. From leveled to 10” of...

Lumpskie

Well-Known Member

- Joined

- Nov 11, 2021

- Messages

- 261

- Reaction score

- 441

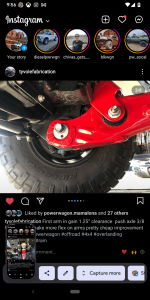

I saw this on Instagram... Pretty cool. This guy replaced the frame side articulink bushing with a 3.0 joint. Less slop, but still maintains flex, since all the magic happens at the axle anyways.

View attachment 39092

I've thought about doing this in the past. From my tests, I wasn't getting bind at the rearward joint. (80 series Land Cruiser guys used to to this as well. They would either replace the rear joint with a spherical bushing like this or add a joint to allow for longitudinal rotation.) In my Land Cruiser experience, though, this joint didn't really provide extra performance. The bind in the radius arms came in the axle side joints. Now, I know that the articulink already addresses axle side bind with the added joint. But, I'm curious to see where the bind in a stock articulink really happens... and if it really fully binds at all. Do you know what springs and shocks this rig is using? I'm wondering if he is trying to do a version of a long travel suspension on stock-like radius arms. (which I think is a cool idea) Maybe if you are trying to run 14" travel shocks on radius arms, I could see this really coming into play. Keep this thread updated as this thing gets tested!

Crusty old shellback

Well-Known Member

- Joined

- Apr 10, 2021

- Messages

- 2,951

- Reaction score

- 4,581

Finally found this old thread.

hdrams.com

hdrams.com

Has anyone else read thru this?

Metacloak has a similar radius arm to what this guy did. They also had a special Johnny joint they sell that may be worth looking into.

Metalcloak Suspension Upgrade

My truck is a 21 2500 Crew, short bed, Hemi 4x4. I have Power Wagon front springs, Carli sway bar, Thuren track bar, off the shelf Fox shocks, rear 1" spacer under factory springs, Carli track bar bracket, adjustable rear track bar, and Fox rear shocks. I run Mickey Thompson Baja Boss At's in...

Has anyone else read thru this?

Metacloak has a similar radius arm to what this guy did. They also had a special Johnny joint they sell that may be worth looking into.

Darkone

Well-Known Member

Seems like he created his own power wagon. I’d be curious to see his flex/ ride quality vs a stock power wagon. He might have a hair more flex over a power wagon with the sway bar locked due to the torsion sway bar though

Lumpskie

Well-Known Member

- Joined

- Nov 11, 2021

- Messages

- 261

- Reaction score

- 441

@Crusty old shellback Just my opinion but I think the articulink arms would net more flex than those metal cloak ones. The bushings need to actually absorb translational motion at the axle side... not just rotation. Picture the drivers side of the axle wanting to roll forward and the passenger side wanting to roll backward to flex. The only way to allow that motion is to allow the center point of the bushing to displace towards the edge. Spherical bushings wont allow for that where rubber ones will. That's the beauty of the articulink arms, if you as me. They have 3 bushings in front... all of which are rubber. If you look at that thread, it appears that Trail_Wagon's PW has more flex than the OP's rig.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)