My brain kinda smooth today. I was thinking about the PW suspension and cant really figure out what the Articulink on the front radius arms do.

In general: the Ram front suspension is a 3 link: 2 radius arms + track bar. Track bar prevents lateral movement, while the radius arms prevent fore/aft movement.

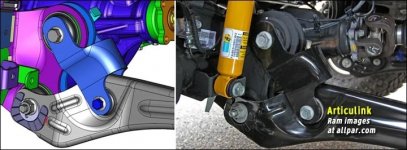

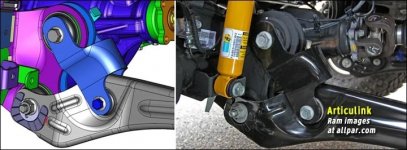

The standard Ram radius arm connects to the axle on 2 points and 1 point on the frame. The PW radius arm retains the same one point on the frame and 2 points on the axle, but the upper point on the axle is connected to the radius arm with a small bracket that is pinned on the radius arm bushing, rather than welded/being of the same part.

I just cant wrap my head around how this extra pinned point / bracket actually does anything. Best i can understand is it allows the axle to slightly roll (About the axis of the axle) forward in droop or rearwards in rebound; but i dont even see what the advantage of this would be? And it seems like it would only work at extreme angles (articulation)

In general: the Ram front suspension is a 3 link: 2 radius arms + track bar. Track bar prevents lateral movement, while the radius arms prevent fore/aft movement.

The standard Ram radius arm connects to the axle on 2 points and 1 point on the frame. The PW radius arm retains the same one point on the frame and 2 points on the axle, but the upper point on the axle is connected to the radius arm with a small bracket that is pinned on the radius arm bushing, rather than welded/being of the same part.

I just cant wrap my head around how this extra pinned point / bracket actually does anything. Best i can understand is it allows the axle to slightly roll (About the axis of the axle) forward in droop or rearwards in rebound; but i dont even see what the advantage of this would be? And it seems like it would only work at extreme angles (articulation)