Pearce

Active Member

3M 4200 may be an option. Works great on everything boat related to keep water out.

More of an adhesive than a sealant.3M 4200 may be an option. Works great on everything boat related to keep water out.

Tahuya is a fun spot, we take our Samurai there and cruise around the trails with the kids. We usually park and watch the built rigs climb up the big obstacles. The last weekend and up to Tuesday were nice weather to go out.Wheeling was fun, went with some folks from a local club to Tahuya forest.

View attachment 70686

And yes, that Ram Rebel went with us the whole way. She was a great driver even though we ended up on some trails that rig didn't belong on, and unfortunately she did not escape without some cosmetic damage.

Climbed up Yellowjacket which was a blast. There was a puddle at the bottom before the first set of slabs that made things a bit tricky at first. The Ram did not go up Yellowjacket.

View attachment 70687

Got hung up a few times but made it top the top with no winching or straps.

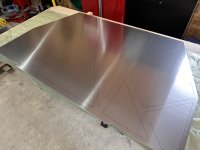

Back to work today. I made the other bottom panel out of the .125.. And apparently didn't take a photo, that seems to be a theme. Anyway it looks the same as the other side.

Then it was on to the first bent panel. I am pushing my brake too hard with this .063.. Hopefully it holds together. I'm definitely going to have to make the corner trim out of something thinner.

After a lot of measuring and some test bends, here's the panel.

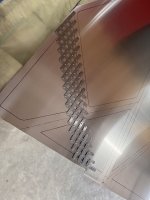

View attachment 70688

Was a little tricky to make - I kind of screwed myself on that inside bend, there are fillet welds there so I couldn't just do an easy 90 - had to do two closely spaced 45's. But it fits.

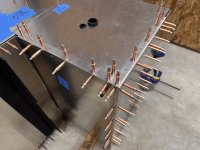

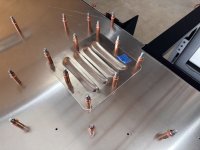

View attachment 70689

View attachment 70690

Now I need to make the same for the other side and then get it pinned in place with some clecos. Still waiting for my order of rivets to show up, they are late..

Oh definitely, that is my plan. I mainly want to make sure no moisture makes its way into the inside of the steel frame via the rivet holes. I am debating whether to also put a bead under the corner trim, there's probably no real point and it may end up causing more mess/lumpiness than it's worth.Have you considered putting a bead of sealant on the frame before riveting on the sheets? I’d think you’d end up with a better seal than just putting a bead from the outside.

Hmm, what about butyl rubber tape like you use on rv roof vents?Oh definitely, that is my plan. I mainly want to make sure no moisture makes its way into the inside of the steel frame via the rivet holes. I am debating whether to also put a bead under the corner trim, there's probably no real point and it may end up causing more mess/lumpiness than it's worth.

Too thick IMHO, I'm just looking for a gasket like smear on the frame before I lay down the panels for the last time and rivet them.Hmm, what about butyl rubber tape like you use on rv roof vents?

Can confirm, I have the same gun. The "auto backoff" is nice as well.Friend that does RV repairs swears by his Milwaukee cordless caulk gun. Beautiful beads and super controllable.

Finally. Not the USPS's finest hour, but Bolt Depot's customer service is top notch.I take it the rivets you needed came in?