gprguy

Well-Known Member

Wheeling was fun, went with some folks from a local club to Tahuya forest.

And yes, that Ram Rebel went with us the whole way. She was a great driver even though we ended up on some trails that rig didn't belong on, and unfortunately she did not escape without some cosmetic damage.

Climbed up Yellowjacket which was a blast. There was a puddle at the bottom before the first set of slabs that made things a bit tricky at first. The Ram did not go up Yellowjacket.

Got hung up a few times but made it top the top with no winching or straps.

Back to work today. I made the other bottom panel out of the .125.. And apparently didn't take a photo, that seems to be a theme. Anyway it looks the same as the other side.

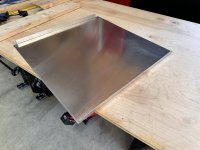

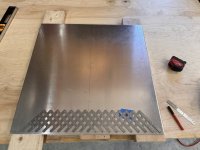

Then it was on to the first bent panel. I am pushing my brake too hard with this .063.. Hopefully it holds together. I'm definitely going to have to make the corner trim out of something thinner.

After a lot of measuring and some test bends, here's the panel.

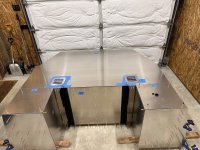

Was a little tricky to make - I kind of screwed myself on that inside bend, there are fillet welds there so I couldn't just do an easy 90 - had to do two closely spaced 45's. But it fits.

Now I need to make the same for the other side and then get it pinned in place with some clecos. Still waiting for my order of rivets to show up, they are late..

And yes, that Ram Rebel went with us the whole way. She was a great driver even though we ended up on some trails that rig didn't belong on, and unfortunately she did not escape without some cosmetic damage.

Climbed up Yellowjacket which was a blast. There was a puddle at the bottom before the first set of slabs that made things a bit tricky at first. The Ram did not go up Yellowjacket.

Got hung up a few times but made it top the top with no winching or straps.

Back to work today. I made the other bottom panel out of the .125.. And apparently didn't take a photo, that seems to be a theme. Anyway it looks the same as the other side.

Then it was on to the first bent panel. I am pushing my brake too hard with this .063.. Hopefully it holds together. I'm definitely going to have to make the corner trim out of something thinner.

After a lot of measuring and some test bends, here's the panel.

Was a little tricky to make - I kind of screwed myself on that inside bend, there are fillet welds there so I couldn't just do an easy 90 - had to do two closely spaced 45's. But it fits.

Now I need to make the same for the other side and then get it pinned in place with some clecos. Still waiting for my order of rivets to show up, they are late..