2019+ LIFTER FAILURE:

I’ve had quite a lot of requests to document these.

If you have had a lifter failure, I’d like to record your trucks information. The goal here is to see how many of these failures have occurred, as well as document basic data surrounding the failure. You can open the form to view it prior to filling it out, that way you can see if there’s information you need to collect prior to filling it out and submitting it. I’ll be using this reporting form to gather data. I will transpose the information onto a publicly viewable spreadsheet as the forms get submitted. Any questions or feedback please comment below.

You can find the form at this link:

forms.gle

forms.gle

You can view the spreadsheet results here:

Lifter Failure Spreadsheet

I’ve had quite a lot of requests to document these.

If you have had a lifter failure, I’d like to record your trucks information. The goal here is to see how many of these failures have occurred, as well as document basic data surrounding the failure. You can open the form to view it prior to filling it out, that way you can see if there’s information you need to collect prior to filling it out and submitting it. I’ll be using this reporting form to gather data. I will transpose the information onto a publicly viewable spreadsheet as the forms get submitted. Any questions or feedback please comment below.

You can find the form at this link:

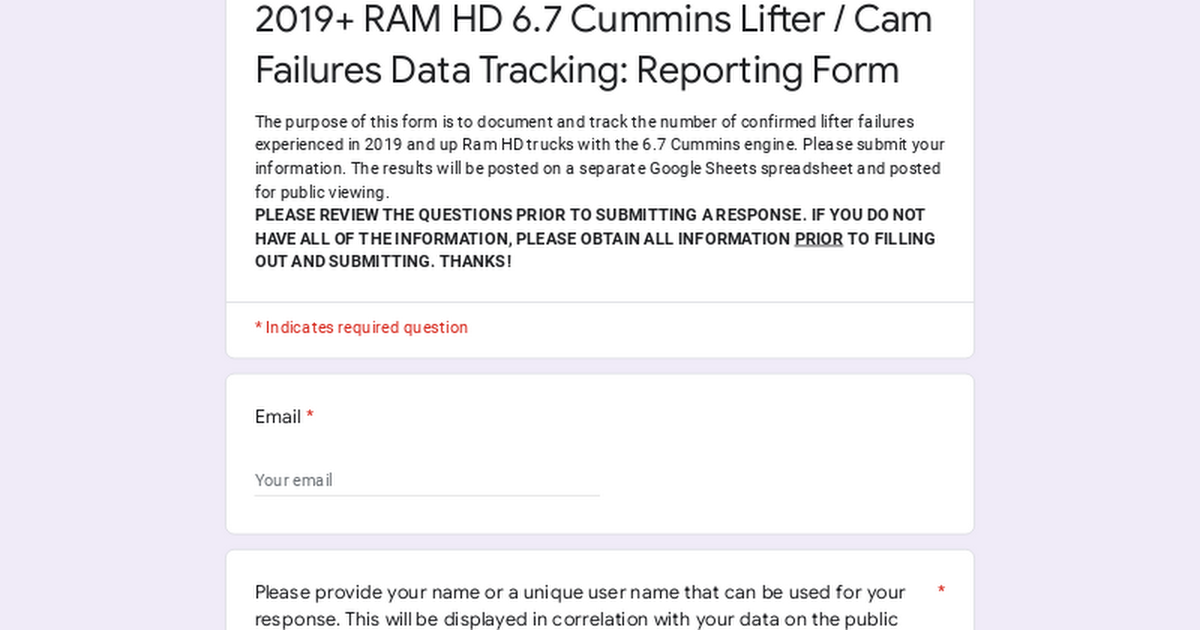

2019+ RAM HD 6.7 Cummins Lifter / Cam Failures Data Tracking: Reporting Form

The purpose of this form is to document and track the number of confirmed lifter failures experienced in 2019 and up Ram HD trucks with the 6.7 Cummins engine. Please submit your information. The results will be posted on a separate Google Sheets spreadsheet and posted for public viewing...

forms.gle

forms.gle

You can view the spreadsheet results here:

Lifter Failure Spreadsheet

Last edited: