gprguy

Well-Known Member

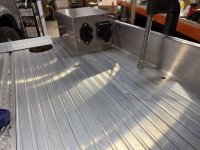

Busy few days. Been working away at the tie down reinforcements as time allows. Both rears and the driver's front are done, I need to do the passenger front/mid and then it'll be on to the next thing.

Here's the underside of one of the rear rings. The idea is angle iron for starters..

And then a piece of 3/16" plate below those, bolted to the tie down. All of the forces on these rings are pulling upwards, so putting the plate below the angle makes sense.

The welds need some more work (I hate welding overhead), but this should be plenty of metal - it's more reinforcement than the same rings use on my enclosed inTech trailer and those are designed to carry a similar amount of weight tied to them.

From above with temporary hardware - all 8 holes are in use.

The rears are both identical. The passenger front is a little more complicated because some fool put an aluminum crossmember in the way.

That one is also finished, so it'll be on to the last one tomorrow. But first, I took a detour today to play amateur machinist.

The next and hopefully last part of the bed build will be to make a stop/lip at the front of the bed for the camper to push against. More on that later, but one of the bolts to fasten it down is right above the midship fuel tank where it's not easily accessible to put a nut on it. So instead of the 1/2" fasteners with nuts that will hold down the majority of the front stop, this particular one gets a 5/8" bolt and threading the spacer itself. The spacer material is 1" DOM with 1/2" ID. To tap it to 5/8" it has to be drilled out to 17/32" as seen above. That was the quick part..

Tapping it took about an hour, but it came out great.

That's one beefy stainless bolt.

Back to that last tie down mount tomorrow.

Here's the underside of one of the rear rings. The idea is angle iron for starters..

And then a piece of 3/16" plate below those, bolted to the tie down. All of the forces on these rings are pulling upwards, so putting the plate below the angle makes sense.

The welds need some more work (I hate welding overhead), but this should be plenty of metal - it's more reinforcement than the same rings use on my enclosed inTech trailer and those are designed to carry a similar amount of weight tied to them.

From above with temporary hardware - all 8 holes are in use.

The rears are both identical. The passenger front is a little more complicated because some fool put an aluminum crossmember in the way.

That one is also finished, so it'll be on to the last one tomorrow. But first, I took a detour today to play amateur machinist.

The next and hopefully last part of the bed build will be to make a stop/lip at the front of the bed for the camper to push against. More on that later, but one of the bolts to fasten it down is right above the midship fuel tank where it's not easily accessible to put a nut on it. So instead of the 1/2" fasteners with nuts that will hold down the majority of the front stop, this particular one gets a 5/8" bolt and threading the spacer itself. The spacer material is 1" DOM with 1/2" ID. To tap it to 5/8" it has to be drilled out to 17/32" as seen above. That was the quick part..

Tapping it took about an hour, but it came out great.

That's one beefy stainless bolt.

Back to that last tie down mount tomorrow.

Last edited: