kobra

Well-Known Member

- Joined

- Oct 25, 2020

- Messages

- 470

- Reaction score

- 961

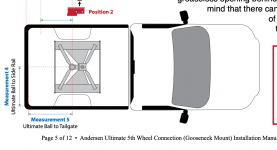

Here are the installation instructions... https://help.andersenhitches.com/install-ultimate-5th-wheel-connection

For many 5th wheel hitches, the adapter is mounted behind the 5th wheel pin, which means the overall offset behind the goose ball is about 2"... my prior 5th was totaled and I haven't taken delivery of my new one so no photos of my setup.

As to your math, I have no idea on what that math is; can you explain?

Because if it's simply that a ball behind the axle lowers GVWR then I don't think that's the whole story; the new gen GMC's have moved the goose ball 2" behind prior gens and none of their GVWR's were lowered, and some were increased.

But as to what photos you're looking for? Sorry I have no idea what you are getting at...

B

For many 5th wheel hitches, the adapter is mounted behind the 5th wheel pin, which means the overall offset behind the goose ball is about 2"... my prior 5th was totaled and I haven't taken delivery of my new one so no photos of my setup.

As to your math, I have no idea on what that math is; can you explain?

Because if it's simply that a ball behind the axle lowers GVWR then I don't think that's the whole story; the new gen GMC's have moved the goose ball 2" behind prior gens and none of their GVWR's were lowered, and some were increased.

But as to what photos you're looking for? Sorry I have no idea what you are getting at...

B