I've been working on the bed edge trim the last few days. My plan is to get the main parts done now, and do the corner caps after our first trip. The corners will look a little ragged till then, but I just don't have the time I don't think.

So anyway, the edges need various bits trimmed out for the fuel fillers and the wheel wells. We're making the trim out of 2x4" 1/8" thick aluminum angle, so we can carefully use a trim router with a carbide bit similar to doing formica countertops.

First, notch the top edge for the fuel fillers using a flush cut bit with the bearing at the bottom.

Next we need to notch around the plastic fuel fill necks. I traced the bottom profile with some paper, scanned that into Fusion 360, and traced it to make a guide that I 3D printed.

Moved over to the fab table, and switching to the router bit with the bearing at the top, I can cut around the pattern.

Forgot to take an after picture, but they fit nicely.

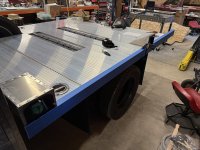

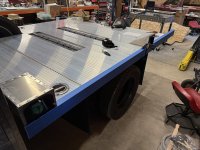

Here's the other pieces, all fit up around the bed.

Last, I need to cut some wheel arches. Again, I made a 3D printed template. This time in two pieces since it's so big, joined with a dovetail.

Over on the table, part way through the cut.

All done.

Pretty happy with the results.

This is with the suspension almost dropped, I dropped it the last 1/4" afterwards and there's still plenty of clearance.

That's where I am at, tomorrow I drill a bunch of holes and start attaching the trim.