gprguy

Well-Known Member

Busy few days getting odds and ends done, lining things up for the next couple weeks.

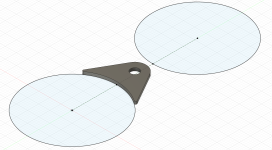

Stainless piano hinges, weatherstripping, a couple of CNC Plasma cut stainless brackets to help reinforce the tail pipe, and a ton of aluminum strips I sheared to become trim on the box.

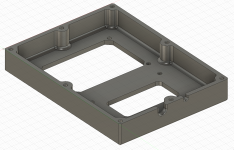

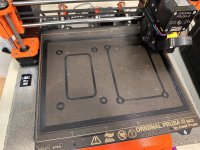

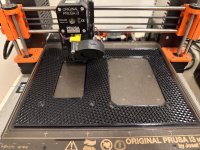

Meanwhile, I started printing a new copy of the enclosure for the controls inside the box. The differences are this one has a textured front and is printed out of PETG instead of PLA so it will take some higher temperatures. Here's the start of the 14 hour print job.

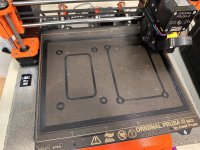

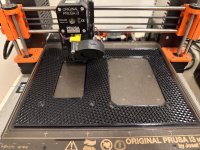

I watched it for about 3 hours to make sure it got started well. Murphy was watching, because 30 minutes after I left there was an hour power outage and I returned the next day to this aborted job.

Ah well, frustrating but it happens. Started over and the next day I came back to this nice finished product.

Much better and I like the textured finish. Installed the melt in threaded inserts and this will get set aside for a while - I'll swap it out once I am done building the cabinet doors.

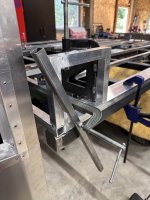

Back to the truck. I bent up the trim for the top edges of the box now that the sikaflex is set that I used to glue the sides on. After that, drill and cleco.

I have a few more trim pieces bent up that just need fitting and holes and they will be ready to go on. Back at it tomorrow.

Stainless piano hinges, weatherstripping, a couple of CNC Plasma cut stainless brackets to help reinforce the tail pipe, and a ton of aluminum strips I sheared to become trim on the box.

Meanwhile, I started printing a new copy of the enclosure for the controls inside the box. The differences are this one has a textured front and is printed out of PETG instead of PLA so it will take some higher temperatures. Here's the start of the 14 hour print job.

I watched it for about 3 hours to make sure it got started well. Murphy was watching, because 30 minutes after I left there was an hour power outage and I returned the next day to this aborted job.

Ah well, frustrating but it happens. Started over and the next day I came back to this nice finished product.

Much better and I like the textured finish. Installed the melt in threaded inserts and this will get set aside for a while - I'll swap it out once I am done building the cabinet doors.

Back to the truck. I bent up the trim for the top edges of the box now that the sikaflex is set that I used to glue the sides on. After that, drill and cleco.

I have a few more trim pieces bent up that just need fitting and holes and they will be ready to go on. Back at it tomorrow.