Searched, but didn't see anything. Thinking about loading heavy gear into the truck, and my back ain't what it used to be. Has anybody added one of those smaller cranes to their truck for loading stuff like generators, sliding 5th wheel hitches, engine blocks, etc.? Cargo in the 200-500 lbs. range.

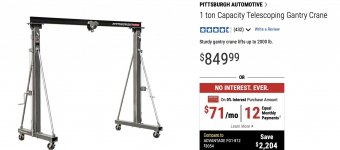

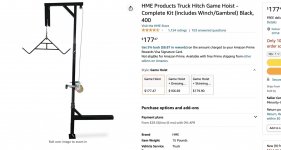

Searched around the web, but most truck cranes are too big, or stick up to high. On the smaller end, something like this might fit the bill:

I like this idea because it stows below the bed line, and could be adapted to be easily removed, and/or add a hand winch to lift cargo off the ground. But there may be better options out there I'm not aware of. Just wondering what others have used to load awkward 250 lbs. items without needing a friend to lend a hand, or using a ramp to roll stuff into the bed of the truck.

Searched around the web, but most truck cranes are too big, or stick up to high. On the smaller end, something like this might fit the bill:

I like this idea because it stows below the bed line, and could be adapted to be easily removed, and/or add a hand winch to lift cargo off the ground. But there may be better options out there I'm not aware of. Just wondering what others have used to load awkward 250 lbs. items without needing a friend to lend a hand, or using a ramp to roll stuff into the bed of the truck.