Redfour5

Well-Known Member

- Joined

- Nov 25, 2021

- Messages

- 366

- Reaction score

- 262

This guy

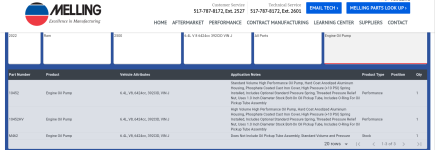

with an 11 year background as a high level tech having gone to their "University" thinks he has figured it out. It's not pressure as such that is the problem, but VOLUME at low pressure that is a primary cause. This is the video that explains his thesis, watch at 10 minutes to cut to the chase. He has other videos where he puts different pumps into hemis. He even has an engineer (GM) who specifically works in this area and that guy agrees with him. He addresses another popular video where a mechanic explains his thesis and he doesn't disagree with the guy but explains more on what that one guy states and why his solution would address it.

I know many people have wondered about the "hemi tick" problem as a long term thing 6.4 owners might have to deal with over time. In doing my research, one, it can happen to any of them as my old 2015 5.7 in an Outdoorsman will attest to... There are stories of Hemi's in police fleets, in particular, suffering as they idle the cop cars so much. I live in MT and have seen temps as low as 41 below and use my remote start for a good four months out of the year on a pretty consistent basis so that may be been an underlying issue for me.

Essentially, he tears down various pumps and installs them and tests them in various other videos and it sure couldn't hurt as they are a relatively easy switchout. My question is that IF this is such an easy fix that would prevent a lot of warranty paid for problems, why doesn't Ram (Chrysler/FCA/STellantis whoever owns them now) just put these pumps on as standard equipment. It would seem that economies of scale and single unit variables alone would make it worth it.

AND, why doesn't anyone who worked or works for RAM or is retired from them or someone address this issue in a forum or something. It's always third parties. Like I said, I had the "lesser" issue of the bolts breaking/manifold in my 5.7, but this seems to be a documented problem in 6.4's to a lesser degree and very distinct in 5.7's.

I know many people have wondered about the "hemi tick" problem as a long term thing 6.4 owners might have to deal with over time. In doing my research, one, it can happen to any of them as my old 2015 5.7 in an Outdoorsman will attest to... There are stories of Hemi's in police fleets, in particular, suffering as they idle the cop cars so much. I live in MT and have seen temps as low as 41 below and use my remote start for a good four months out of the year on a pretty consistent basis so that may be been an underlying issue for me.

Essentially, he tears down various pumps and installs them and tests them in various other videos and it sure couldn't hurt as they are a relatively easy switchout. My question is that IF this is such an easy fix that would prevent a lot of warranty paid for problems, why doesn't Ram (Chrysler/FCA/STellantis whoever owns them now) just put these pumps on as standard equipment. It would seem that economies of scale and single unit variables alone would make it worth it.

AND, why doesn't anyone who worked or works for RAM or is retired from them or someone address this issue in a forum or something. It's always third parties. Like I said, I had the "lesser" issue of the bolts breaking/manifold in my 5.7, but this seems to be a documented problem in 6.4's to a lesser degree and very distinct in 5.7's.