Couple things.

You should not be able to turn a wheel by hand with the emergency cable/pin pulled. No way, no how. I can tell you with certainty, the brakes will lock with full, constant, not PWM 12V applied from the RV battery. Ours on our old 04 Cougar got hung on the hitch once and stopped us dead in our tracks making a turn on a small town main street.

What color are the magnet wires? The 6K axles should have white or black wires (green wires are lower power magnets).

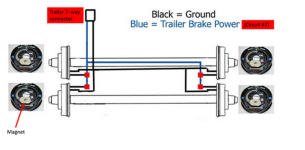

Ensure the wiring is in parallel and not in series.

Each magnet should have one lead tied to power, and one lead tied to ground - preferably the ground wire and not a chassis or frame ground.

To properly measure each magnet resistance, you need to disconnect and measure them individually. The combined resistance doesn't tell you much if one is shorted internally. They should each measure 3.2-3.5 Ohms.

View attachment 39836

Is it possible the axles were installed backwards? That would put the brake assembly backwards. The actuator arm and short pad should be in the leading position, the long pad in the trailing position.

(left side = LH assembly shown)

View attachment 39835