jfreemanak

New Member

- Joined

- Jun 2, 2021

- Messages

- 3

- Reaction score

- 5

I mostly post on Cummins forum, but have not had luck getting an answer. So I thought I would try here. Background: Back in April, I installed the bed LED light kit from Mopar. I had read that our trucks are prewired for the bed lights (wrong) and thought I had found the connector on the back of the hitch (turns out the connector was for a proximity sensor to unlock the tailgate). Since the Mopar LED kit I bought was not specifically for my year, I cut off the connector and spliced the lights in. I then used AlfaOBD to enable the truck bed lights.

Of course that did not work, and I found out that wasn't the right connector. I then used AlfaOBD to turn everything back off. However, after making those changes (and cutting off the female connector for the proximity sensor that my truck did not come with), I noticed that when I open the door and the lights come on, only the passenger (right) front LED parking lights come on now. When the truck is running or in the on position, both the front parking LED lights come on (see pictures). I have scanned all my modules for codes, but have nothing.

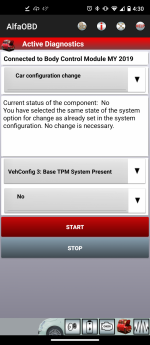

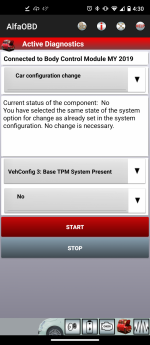

I have been just dealing with it since April (and the many people that tell me my drivers side front lights are out...) but finally brought it to the dealership today to have everything reset to factory defaults.. I have spent many hours myself trying to figure out what is going on, but I have no idea. The dealer says they reset everything ($170) but the problem still exists. I am not sure that I believe them, because I had turned off my TPMS sensors pretty much as soon as I got the truck in early 2020, and those are still listed as not present (which they were when I bought the truck). I went back in to talk with the service advisor about it, and he said that was everything they could do.

So, does anyone know what is going on? Is there a master tech that could advise me what procedure I should ask for at the dealer to have my BCM reset specifically? Am I able to do a full factory reset with AlfaOBD?

I appreciate any help.

Of course that did not work, and I found out that wasn't the right connector. I then used AlfaOBD to turn everything back off. However, after making those changes (and cutting off the female connector for the proximity sensor that my truck did not come with), I noticed that when I open the door and the lights come on, only the passenger (right) front LED parking lights come on now. When the truck is running or in the on position, both the front parking LED lights come on (see pictures). I have scanned all my modules for codes, but have nothing.

I have been just dealing with it since April (and the many people that tell me my drivers side front lights are out...) but finally brought it to the dealership today to have everything reset to factory defaults.. I have spent many hours myself trying to figure out what is going on, but I have no idea. The dealer says they reset everything ($170) but the problem still exists. I am not sure that I believe them, because I had turned off my TPMS sensors pretty much as soon as I got the truck in early 2020, and those are still listed as not present (which they were when I bought the truck). I went back in to talk with the service advisor about it, and he said that was everything they could do.

So, does anyone know what is going on? Is there a master tech that could advise me what procedure I should ask for at the dealer to have my BCM reset specifically? Am I able to do a full factory reset with AlfaOBD?

I appreciate any help.