"Insert Tab A into Slot B":

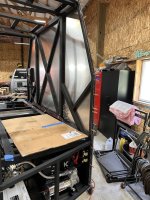

I had originally hoped to lift the box up with the 2 post lift, but the arms are too long and it just wasn't going to work. So back to old trusty:

We took our time and everything went to plan.

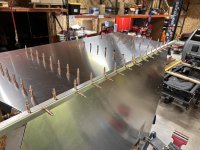

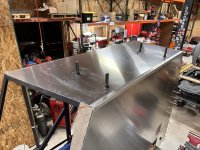

Not the easiest spot in the garage to get a good overall shot, but I just have the bolts in loosely. I'll move it tomorrow.

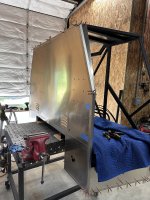

I'm really pleased how it came out. Hopefully I can speed things up from here even though there are still a million things to do.

The bare minimum to hit the road - build the door frames and doors, skin the back of the box, and build the flatbed and tailboard. I can start working several of these in parallel so hopefully things move along quickly enough to salvage at least part of the summer. I'll probably do the bare minimum wiring as well just to get on the road.

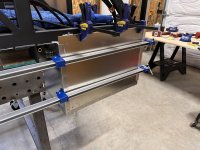

Also, my extended/rerouted CHMSL wiring and camera extensions finally get their time to shine. The door flexi boot worked great:

I suspect the CHMSL mount will get temporarily sealed up for now since that's going to be a fiddly project to make it look nice. But at least the cable is long enough.

Overall I am really pleased - the bolts lined up easily, the box looks great to me, and the ground clearance is plenty. The DPF hangs down probably 4-6" more than the box does. Onward...