what about the pinch weld issues??Honestly, I wouldn't spend the additional cost and headache for the OEM steps. The AMP steps have proven to be as reliable a platform as any OEM and are not only cheaper to add after but deploy and retract faster.

Ram Heavy Duty Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mopar Power Deployable Running Boards

- Thread starter johanh13

- Start date

UglyViking

Well-Known Member

- Messages

- 1,410

- Reaction score

- 1,788

- Points

- 113

I may be alone, and I'll admit I've not followed this closely, but I've had no issues with my Amp steps on my 19what about the pinch weld issues??

El Toro Blanco

Member

- Messages

- 52

- Reaction score

- 50

- Points

- 18

I've had no issues with my '21 2500 CC either.I may be alone, and I'll admit I've not followed this closely, but I've had no issues with my Amp steps on my 19

I’m not sure where you are getting the idea that the dash needs to be removed?Is dash removal the only option if I find the OEM power boards? What exactly has to be removed?

Have you read this thread all the way through from the beginning?

Maybe I misread. Im a math guy haha. Did you not say the dash needed removed? ThanksI’m not sure where you are getting the idea that the dash needs to be removed?

Have you read this thread all the way through from the beginning?

I did give someone a “scenario” of what would be involved if a dealer was to install them after the fact. I doubt a dealership would ever take on this project, and if they do (knowing what wire harnesses are involved), the price to do it would be absolutely astronomical.Maybe I misread. Im a math guy haha. Did you not say the dash needed removed? Thanks

If there is a dealership that claims they can add the power side steps after the fact, I would make absolute certain that they aren’t talking about AMP steps, or they aren’t talking about a 1500 (because there is a mopar kit for adding them after for the 1500’s).

The thing about the power steps is, there’s no factory kit for them to add later. You can’t just go to a dealer and ask them to install the steps, because they don’t build custom harnesses. The only thing they know is to replace the harnesses in the truck with the ones that have provisions for the steps. In this case, that would involve replacing the two chassis harnesses and the dash harness, which involves removing the entire dash. Now, if mopar was to release a kit to add the factory power steps, the add-on harness that they design for the kit would probably be similar to the one I suggested to build. As far as warranty for having the dealer install it- when the dealer adds the sales code to enable the feature, it shows up on your VIN build as “dealer installed option”, so only the dealership that did the install of the kit would take care of a warranty issue with it. It’s not like the factory warranty where you can take the truck to any FCA dealer for warranty work.

Splzhaul

Active Member

- Messages

- 71

- Reaction score

- 107

- Points

- 33

I had my dealer add the ram factory ones at the dealer. They went on the 1500 eco diesel I bought this year. I bought a 3500 Limited from same dealer last year and got the running boards on it from the factory. I love the running boards.The dealer did a great job and there has been no issues with them. The dealer is Kernersville dodge ,Kernersville NC.I did give someone a “scenario” of what would be involved if a dealer was to install them after the fact. I doubt a dealership would ever take on this project, and if they do (knowing what wire harnesses are involved), the price to do it would be absolutely astronomical.

If there is a dealership that claims they can add the power side steps after the fact, I would make absolute certain that they aren’t talking about AMP steps, or they aren’t talking about a 1500 (because there is a mopar kit for adding them after for the 1500’s).

Mopar offers a power side step kit that can be installed after the fact for the 1500’s.I had my dealer add the ram factory ones at the dealer. They went on the 1500 eco diesel I bought this year. I bought a 3500 Limited from same dealer last year and got the running boards on it from the factory. I love the running boards.The dealer did a great job and there has been no issues with them. The dealer is Kernersville dodge ,Kernersville NC.

There is no such kit offered for the heavy duty Rams, hence the reason for this thread.

6.7PatriotBlue22

Member

- Messages

- 45

- Reaction score

- 27

- Points

- 18

But for a novice (like myself) is the best route to modify the 1500 kit harness or make the custom one you helped Jonah with (or can I pay you to make me a custom harness?)Mopar offers a power side step kit that can be installed after the fact for the 1500’s.

There is no such kit offered for the heavy duty Rams, hence the reason for this thread.

Last edited:

Yep. Crazy. Wonder if they will offer the same on the 2500s at some point. I am reluctant to get the AMP boards due to the common pinch weld issue.Mopar offers a power side step kit that can be installed after the fact for the 1500’s.

There is no such kit offered for the heavy duty Rams, hence the reason for this thread.

Well, look at it this way to help you decide what to do:Yep. Crazy. Wonder if they will offer the same on the 2500s at some point. I am reluctant to get the AMP boards due to the common pinch weld issue.

The 1500’s started getting the power side steps for 2019, and they offer a kit for them right away. The heavy duty rams have had the power side step option for the same amount of time, and they haven’t made a kit for them.

Redfour5

Well-Known Member

- Messages

- 400

- Reaction score

- 321

- Points

- 63

So, what CAD program did you use to put that together?Here’s some info I put together on the power steps. It includes the schematic, connector views, and pinouts. The wire sizes are listed in mm2, so convert those to AWG when choosing wire. https://drive.google.com/file/d/1aWISv7rrkxYO31HQMoymEi8AOSLDDUv3/view?usp=drivesdk

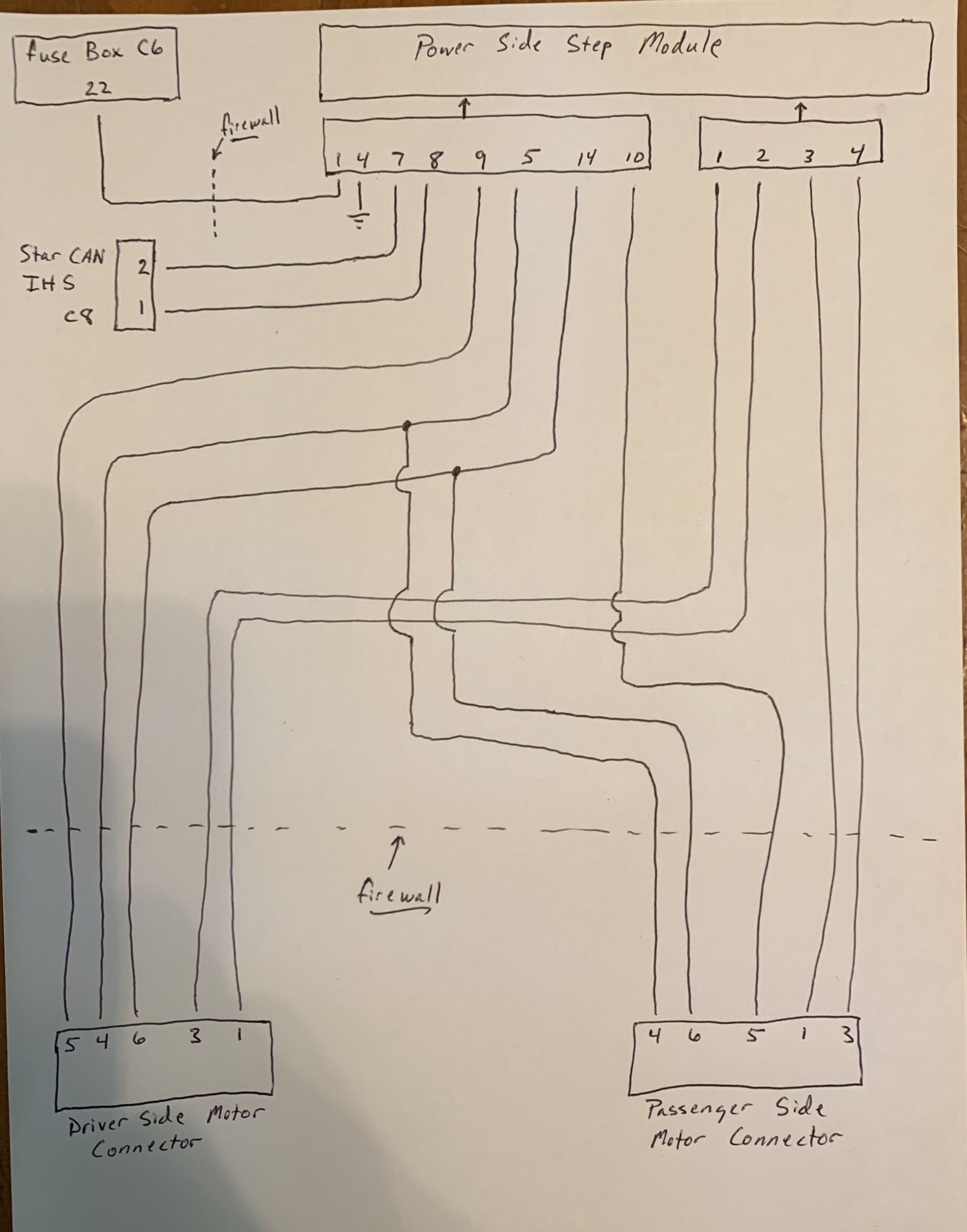

The way I would do this is, I would install all the parts first, then the harness. Using your best guess, cut all the wires long enough (longer) to reach their appropriate spots with all wires originating at the power step module. This method will bypass all inline connectors, and remove all doubt on what partial wiring may or may not be present. If the fuse box C6 connector pin 22 wire is already present, just remove it and install your wire. No sense in figuring out which connector it terminates at, and adding more terminal part numbers in the mix. Assemble the wires to the C1 and C2 power step module connectors, and leave the other connectors off for now so you can pass the wire bundle through one location in the firewall that you choose. Then, once you branch off the wiring to go to the two motor connectors and fuse box connector, cut them to length and finish pinning the wires to the rest of the connectors. Attach the ground wire near the power step module, as there will already be a common ground bolt at the footwell in that vicinity. There are detailed pics of the star can IHS connector block location in the above document.

Use Tesa tape for interior wiring, and use super 33 tape and split loom for exterior wiring.

I’m no good at doing drawings on a computer, but here’s a crude sketch-

Resurrecting this thread. I just traded in my 3500 tradesman for a 2500 limited. Window sticker shows power deployable running boards under standard equipment, but wheel to wheel chrome side steps under optional equipment. My question is should the wiring harness include everything to hook up mopar power steps?

Attachments

I guess if anyone knows, it would be @Jimmy07 . Any ideas?Resurrecting this thread. I just traded in my 3500 tradesman for a 2500 limited. Window sticker shows power deployable running boards under standard equipment, but wheel to wheel chrome side steps under optional equipment. My question is should the wiring harness include everything to hook up mopar power steps?

Hi everyone. This is a great thread and I've learned a lot from @Jimmy07 and @johanh13.

I picked up a 2022 Ram Big Horn which was converted by AEV into the Prospector XL. When AEV did the conversion they added the Mopar power steps as they were not optioned on the Big Horn.

After about one month of ownership, the power boards started working (and not working) in an erratic manner. Sometimes they work, sometimes they don't. Sometimes they deploy and retract while driving.

Took it into a local Ram dealer and they had no idea what they were looking at. Said they are aftermarket and cant service them. Charged me ~250 bucks. Unreal.

1. Started with disconnecting both batteries to reset the system. Seemed to help for a bit and then it reverted back to unpredictable performance.

2. Tested the grounds and they seemed ok

3. I do not have options in Uconnect for the steps.

4. Considering the power step module might be bad but interested in steps you all think I should take before I replace?

Note: Yes this is all covered under warranty by AEV but I kinda want to just figure it out on my own.

I picked up a 2022 Ram Big Horn which was converted by AEV into the Prospector XL. When AEV did the conversion they added the Mopar power steps as they were not optioned on the Big Horn.

After about one month of ownership, the power boards started working (and not working) in an erratic manner. Sometimes they work, sometimes they don't. Sometimes they deploy and retract while driving.

Took it into a local Ram dealer and they had no idea what they were looking at. Said they are aftermarket and cant service them. Charged me ~250 bucks. Unreal.

1. Started with disconnecting both batteries to reset the system. Seemed to help for a bit and then it reverted back to unpredictable performance.

2. Tested the grounds and they seemed ok

3. I do not have options in Uconnect for the steps.

4. Considering the power step module might be bad but interested in steps you all think I should take before I replace?

Note: Yes this is all covered under warranty by AEV but I kinda want to just figure it out on my own.

I would start by finding out whether they are mopar or amp boards. If they are mopar, I would check the connectors to the motors, the PSSM, and CAN bus. If they are mopar then it's really easy to add the the option to deploy from your screen using alfaOBD. Another thing to check would be the wires between the CAN bus and PSSM, they should be twisted with about 3 turns per inch (not too sure on what the exact number of twists should be)... FWIW, my boards have worked flawlessly so far!Hi everyone. This is a great thread and I've learned a lot from @Jimmy07 and @johanh13.

I picked up a 2022 Ram Big Horn which was converted by AEV into the Prospector XL. When AEV did the conversion they added the Mopar power steps as they were not optioned on the Big Horn.

After about one month of ownership, the power boards started working (and not working) in an erratic manner. Sometimes they work, sometimes they don't. Sometimes they deploy and retract while driving.

Took it into a local Ram dealer and they had no idea what they were looking at. Said they are aftermarket and cant service them. Charged me ~250 bucks. Unreal.

1. Started with disconnecting both batteries to reset the system. Seemed to help for a bit and then it reverted back to unpredictable performance.

2. Tested the grounds and they seemed ok

3. I do not have options in Uconnect for the steps.

4. Considering the power step module might be bad but interested in steps you all think I should take before I replace?

Note: Yes this is all covered under warranty by AEV but I kinda want to just figure it out on my own.

Thanks man! Yes they are for sure Mopar ... PSSM is in place and wired up. The options sheet from AEV clearly state Mopar and I have installed AMP boards several times so understand the setup on those.I would start by finding out whether they are mopar or amp boards. If they are mopar, I would check the connectors to the motors, the PSSM, and CAN bus. If they are mopar then it's really easy to add the the option to deploy from your screen using alfaOBD. Another thing to check would be the wires between the CAN bus and PSSM, they should be twisted with about 3 turns per inch (not too sure on what the exact number of twists should be)... FWIW, my boards have worked flawlessly so far!

Will trace the connections to ensure they are all solid. Guess I need to start pulling some dash pieces. Hard to get to the PSSM from the side dash panel.

CAN has a ton of connections on it ... should be fun to dig out which one is the PSSM connection ha.

Im waiting on the security bypass connector for the alphaOBD setup ... should be here soon.

If you still have any of these, please PM, I could use one. Thank you!I have some extra connectors... do you just need the gray one? I have the bare-naked connectors....

Here is what I have left...If you still have any of these, please PM, I could use one. Thank you!