Under load under certain conditions I've always been able to hear a very slight rattle from inside the cab, but it honestly sounded like something deep in the dash was resonating at a certain speed/RPM/load. If the radio was on you'd never notice it.

Anyway, this evening I had the door open/window down, happened to rev my truck's engine in my driveway, and noticed the ticking. I never (and still don't) notice any noise at idle but by the time the truck is at 1750 RPM it sounds like someone is shaking a metal coffee can full of gravel. It's easily noticeable from outside the truck, but still really inaudible from inside.

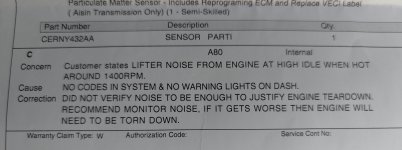

I've had all my maintenance done at the dealer, oil changes at the computer-recommended intervals, services per the maintenance guide, no regeneration issues (or issues at all, really), the truck's not making oil, and I haven't done a whole heck of a lot of towing. I have 35K miles on the truck right now and managed to get a dealer appointment for tomorrow so I can get the issue on paper before my warranty is up (although it sounds like this will likely be under the powertrain warranty anyway).

I'll get a recording posted tomorrow, but believe me, the ticking is pretty audible. My wife heard it instantly when I revved the motor to 1750 RPM and then noticed it at lower RPMs also. Is the dealer really going to tell me to pound sand over this?