ramblinChet

Drinks Alone

- Messages

- 635

- Reaction score

- 3,018

- Points

- 93

You may recognize these Schwaben Ear-Type Clamp Pliers, designed for use with Oetiker clamps in automotive and industrial applications. Oetiker clamps provide uniform compression, compensate for component tolerances, and enable fast, reliable installation. To select the correct clamp diameter, install the hose onto the fitting and measure the hose's outer diameter (OD). The measured OD should be slightly larger than the average value of the clamp’s diameter range. A clamp is adequately closed when the ear width is reduced by at least 40% using the appropriate closing force. For my project, I needed only a foot of fuel hose but opted for a 25-foot roll of Continental 3/16" ID Fuel Line/Emission Control Hose (SAE 30R7). This hose, constructed with Hysunite and Chemigum, is rated for temperatures up to 250°F and offers versatility for multiple applications.

Ear-Type Clamp Pliers function by crimping Oetiker ear clamps to create a secure, leak-proof seal on hoses or tubes. The user positions the clamp around the hose and fitting, then places the pliers’ jaws over the clamp’s ear. Squeezing the handles applies precise force, deforming the ear to reduce the clamp’s diameter and lock it in place. Engineered for uniform compression, these pliers ensure a reliable 360° seal. Their jaw configurations accommodate various clamp sizes and are designed for use in confined spaces.

This image illustrates the transition from an accessory to the 5mm OD, 2mm ID fuel line used by Eberspächer, Wallas, and Webasto diesel heaters. Here, I connect a Hengst Filtration diesel fuel filter to the Continental 3/16" ID hose, secured with two Oetiker clamps at each end for a robust, leak-free connection.

I also incorporated a premium quick-disconnect for the diesel fuel line to allow easy removal of my camper without fully disconnecting the fuel line from the truck’s fuel tank or the diesel heater inside the camper. I selected a Goodridge chrome-plated brass quick-disconnect for $100 (shipped) and am eager to evaluate its performance. The Continental hose and Oetiker clamps bridge the disconnect to the standard fuel line, ensuring a secure connection.

Removing the 30-gallon TITAN auxiliary fuel tank from beneath my truck was a daunting task, and reinstalling it after adding wiring, a vent hose, a rollover hose, a primary fill hose, and trimming everything to length was equally challenging. I recall the initial tank installation, which was difficult even with a friend’s help. This time, I completed the task alone, making it even more demanding.

B’laster Surface Shield provides robust protection for a truck’s undercarriage with its lanolin-based formula, effectively preventing rust and corrosion in harsh environments, such as salt-heavy roads. Its moisture-wicking properties form a durable barrier against water and contaminants, offering protection for up to two years. Compared to alternatives like Fluid Film or Woolwax, Surface Shield applies cleaner, is less messy, and adheres better in high-wash areas while remaining safe for rubber, plastics, and electrical components. Its low viscosity ensures excellent creep into crevices for comprehensive coverage, and its non-drying, tacky film resists wash-off, making it ideal for rugged, off-road conditions. I regret not applying this product years ago. In March, I ordered six cans of Surface Shield and two Can-Gun1 spray handles, which provided ample product and performed exceptionally well during application.

Innovative projects often present unique challenges requiring creative solutions. To mount a universal fuel pick-up tube with ears and male M18x1.0mm threads into a double-tapped tank bushing with 1" NPT male and 1/2" NPT female threads, I rejected the simplistic approach of plugging the 1/2" NPT female hole and drilling a new one elsewhere. Instead, I purchased a 1" NPT brass hex head plug, a 17mm drill bit, and an M18x1.0mm tap. I drilled and tapped a hole in the brass hex head, removed the silver solder, knocked off the mounting ears, cleaned the threads, and sealed the modified components with yellow gas-line PTFE tape. This solution ensured a precise, professional outcome.

I’m an ordinary guy with a few close friends, including one I worked with at Siemens VDO and later at NASA Langley Research Center. He’s the finest mechanical engineer I’ve ever known, currently serving as a Senior SME Principal Mechanical Engineer at NASA Langley. With a shared sense of precision, he invited me to his shop to drill, tap, and trim the fuel pick-up for my diesel heater. While there, he showed me his special cutting oil, a can he’s owned since he was 16, working in a small engine repair shop to save for university. An older colleague gifted him the can and wished him well - a gesture from half a century ago. This story reminds us that a small act of generosity can profoundly impact someone’s life.

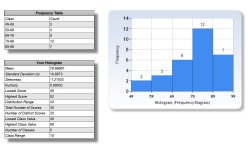

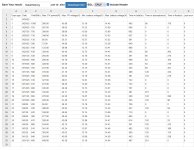

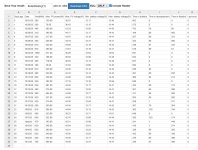

Here, I continue documenting expenses for historical reference.

The fuel pick-up (tank fitting) is now installed, and I expect it to perform reliably. The fuel pump in a Wallas Nordic DT diesel heater, a low-pressure electric pump designed for compact marine or RV heating systems, faces significant challenges when drawing diesel through a hose with an inner diameter (ID) greater than 2mm to a height of six feet. The pump’s limited suction capacity, optimized for 2mm ID hoses and shorter lift heights, struggles with the increased volume and flow resistance of a larger hose. A hose with a >2mm ID demands greater vacuum pressure to overcome the fuel column’s weight, which increases with both height (six feet creates substantial static head pressure) and the hose’s larger internal volume. Additionally, the pump risks cavitation or air ingress due to insufficient priming or sealing, reducing efficiency and potentially stalling. These factors - insufficient vacuum strength, increased fuel weight, and potential air ingress - make consistent fuel flow difficult. This is why I invested extra effort to install a fuel pick-up with a 2mm ID. The inset picture compares the original fuel pick-up to the one I constructed. I hope this solution succeeds, as it operates near the fuel pump’s performance limits. Function is the key...

Ear-Type Clamp Pliers function by crimping Oetiker ear clamps to create a secure, leak-proof seal on hoses or tubes. The user positions the clamp around the hose and fitting, then places the pliers’ jaws over the clamp’s ear. Squeezing the handles applies precise force, deforming the ear to reduce the clamp’s diameter and lock it in place. Engineered for uniform compression, these pliers ensure a reliable 360° seal. Their jaw configurations accommodate various clamp sizes and are designed for use in confined spaces.

This image illustrates the transition from an accessory to the 5mm OD, 2mm ID fuel line used by Eberspächer, Wallas, and Webasto diesel heaters. Here, I connect a Hengst Filtration diesel fuel filter to the Continental 3/16" ID hose, secured with two Oetiker clamps at each end for a robust, leak-free connection.

I also incorporated a premium quick-disconnect for the diesel fuel line to allow easy removal of my camper without fully disconnecting the fuel line from the truck’s fuel tank or the diesel heater inside the camper. I selected a Goodridge chrome-plated brass quick-disconnect for $100 (shipped) and am eager to evaluate its performance. The Continental hose and Oetiker clamps bridge the disconnect to the standard fuel line, ensuring a secure connection.

Removing the 30-gallon TITAN auxiliary fuel tank from beneath my truck was a daunting task, and reinstalling it after adding wiring, a vent hose, a rollover hose, a primary fill hose, and trimming everything to length was equally challenging. I recall the initial tank installation, which was difficult even with a friend’s help. This time, I completed the task alone, making it even more demanding.

B’laster Surface Shield provides robust protection for a truck’s undercarriage with its lanolin-based formula, effectively preventing rust and corrosion in harsh environments, such as salt-heavy roads. Its moisture-wicking properties form a durable barrier against water and contaminants, offering protection for up to two years. Compared to alternatives like Fluid Film or Woolwax, Surface Shield applies cleaner, is less messy, and adheres better in high-wash areas while remaining safe for rubber, plastics, and electrical components. Its low viscosity ensures excellent creep into crevices for comprehensive coverage, and its non-drying, tacky film resists wash-off, making it ideal for rugged, off-road conditions. I regret not applying this product years ago. In March, I ordered six cans of Surface Shield and two Can-Gun1 spray handles, which provided ample product and performed exceptionally well during application.

Innovative projects often present unique challenges requiring creative solutions. To mount a universal fuel pick-up tube with ears and male M18x1.0mm threads into a double-tapped tank bushing with 1" NPT male and 1/2" NPT female threads, I rejected the simplistic approach of plugging the 1/2" NPT female hole and drilling a new one elsewhere. Instead, I purchased a 1" NPT brass hex head plug, a 17mm drill bit, and an M18x1.0mm tap. I drilled and tapped a hole in the brass hex head, removed the silver solder, knocked off the mounting ears, cleaned the threads, and sealed the modified components with yellow gas-line PTFE tape. This solution ensured a precise, professional outcome.

I’m an ordinary guy with a few close friends, including one I worked with at Siemens VDO and later at NASA Langley Research Center. He’s the finest mechanical engineer I’ve ever known, currently serving as a Senior SME Principal Mechanical Engineer at NASA Langley. With a shared sense of precision, he invited me to his shop to drill, tap, and trim the fuel pick-up for my diesel heater. While there, he showed me his special cutting oil, a can he’s owned since he was 16, working in a small engine repair shop to save for university. An older colleague gifted him the can and wished him well - a gesture from half a century ago. This story reminds us that a small act of generosity can profoundly impact someone’s life.

Here, I continue documenting expenses for historical reference.

The fuel pick-up (tank fitting) is now installed, and I expect it to perform reliably. The fuel pump in a Wallas Nordic DT diesel heater, a low-pressure electric pump designed for compact marine or RV heating systems, faces significant challenges when drawing diesel through a hose with an inner diameter (ID) greater than 2mm to a height of six feet. The pump’s limited suction capacity, optimized for 2mm ID hoses and shorter lift heights, struggles with the increased volume and flow resistance of a larger hose. A hose with a >2mm ID demands greater vacuum pressure to overcome the fuel column’s weight, which increases with both height (six feet creates substantial static head pressure) and the hose’s larger internal volume. Additionally, the pump risks cavitation or air ingress due to insufficient priming or sealing, reducing efficiency and potentially stalling. These factors - insufficient vacuum strength, increased fuel weight, and potential air ingress - make consistent fuel flow difficult. This is why I invested extra effort to install a fuel pick-up with a 2mm ID. The inset picture compares the original fuel pick-up to the one I constructed. I hope this solution succeeds, as it operates near the fuel pump’s performance limits. Function is the key...