1FstGPa

Member

- Joined

- Mar 3, 2021

- Messages

- 77

- Reaction score

- 81

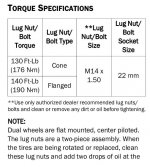

I did some net searches for this and came up with 130 ft/lbs for cone nuts and 140 ft/lbs for flanged nuts.

Now my story and I'll try to keep this short...

Yesterday, I thought I would inspect the cone lug nuts under the caps and verify torque before we headed out the door for our road trip. So I grabbed my trusty clicker torque wrench, a 4" extension and the appropriate socket. I set the torque wrench to 130 ft/lbs and begun the task of checking the torque. The first go around on the 8 lugs showed no sign of socket movement before the wrench "clicked". Personally, I like to see a little movement to proof the setting. So, I set the torque wrench to 140 ft/lbs to test that setting. Again, no socket movement. From here I didn't go higher, but this has me concerned. I am assuming the wheels were installed at the factory without r&r somewhere down the line. I am also assuming my wrench is correct and that the 4" extension has little to no effect on the value of the setting.

Needless to say, I know this is an issue since over tightening the lug nuts can lead to warped rotors.

So, what am I missing here? Should I re-torque to the correct spec if I know what I know or leave it and give it a white collar - the factory knows what they're doing - approach???

Now my story and I'll try to keep this short...

Yesterday, I thought I would inspect the cone lug nuts under the caps and verify torque before we headed out the door for our road trip. So I grabbed my trusty clicker torque wrench, a 4" extension and the appropriate socket. I set the torque wrench to 130 ft/lbs and begun the task of checking the torque. The first go around on the 8 lugs showed no sign of socket movement before the wrench "clicked". Personally, I like to see a little movement to proof the setting. So, I set the torque wrench to 140 ft/lbs to test that setting. Again, no socket movement. From here I didn't go higher, but this has me concerned. I am assuming the wheels were installed at the factory without r&r somewhere down the line. I am also assuming my wrench is correct and that the 4" extension has little to no effect on the value of the setting.

Needless to say, I know this is an issue since over tightening the lug nuts can lead to warped rotors.

So, what am I missing here? Should I re-torque to the correct spec if I know what I know or leave it and give it a white collar - the factory knows what they're doing - approach???