Scott C

New Member

- Messages

- 21

- Reaction score

- 10

- Points

- 3

Apologies in advance for the long-ass post! I was wondering if anyone has experienced the problems we are having or might have an idea.

We are building 2022 Ram 2500 Tradesman 4-door trucks with dual 220-amp alternators. We are powering oil and gas testing equipment through a 5kW pure sine wave inverter all located in the back seat of the trucks. We ran 4/0 SGX cable rated at 120C from one alternator to the other, then from the driver-side alternator to a 400A T-fuse, then to the inverter. Our one way cable run is 18-feet not to include the three feet of cable connecting the two alternators. We ran 4/0 SGX ground cable from the inverter back to the alternator mounting bolt to ensure we have a good ground. We used Burndy 4/0 crimp connectors and a 16-ton hydraulics crimper then shrink wrapped the ends and used black or red split wire loom the entire run, except when passing thru the floorboard. We have triple-checked the wiring and have a good ground with a 0.4VDC total voltage drop over the entire circuit.

So far, power is fine at an 18A load on the AC side at both low and high idle. We are having two issues though. One is that the driver-side alternator is providing most of the power instead of the ECM balancing the load between them. The second issue is the voltage is varying all over the place causing the lights to flicker and the AC blower motor to surge. The truck engine is not surging. Our testing system uses Pulse Width Modulation (PWM) to maintain certain levels of heat in our test system. PWM controls a solid state relay that turns on/off in the millisecond range to control the heating elements. What we have noticed is that the voltage is hopping all over the place from 12.6VDC to 14.2VDC as the PWM controller pulses the electrical demand to the 5 heating units. It has to be the PWM as when the system is at full power heating up the various devices, there is no voltage variation and no surging. The voltage fluctuation continues from the batteries even when we shut off the truck, so it isn't the alternators.

We took the truck to the Ram dealer electrician who said there is no reason for the truck to be doing this. He has built a lot of snow plow and ambulance trucks without these problems. He rewired the truck so the 4/0 cable was attached directly to the batteries instead of the alternator with no improvement. He opened a case to get a Ram engineer to weigh in and said it would be 2-3 days before we would get any info, but 2 hours later he received a response that the truck is fine and it must be our equipment. Pretty much a blow off answer and the dealer isn't happy, but not much they can do I guess. The electrician did say that Ram alternators, unlike Duramax and Ford, do not have a voltage regulator and that the ECM manages it for the entire system.

Our current plan is to run 4/0 cable from each alternator directly to the T-400 fuse and see if this will solve the load balance problem. Based on the results of that, we will then look at an external voltage regulator. We are also looking at options other than PWM for temperature control of our equipment, but that won't fix the load balancing problem.

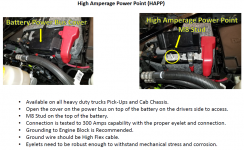

I have attached our current install diagram. The smaller red lines are the OEM 2-gauge wire and the larger ones are 4/0. I did not include the OEM ground wires. I also included a photo of the wiring in the engine compartment.

We would appreciate any thoughts, ideas, or SWAGs since Ram is no help.

Scott

We are building 2022 Ram 2500 Tradesman 4-door trucks with dual 220-amp alternators. We are powering oil and gas testing equipment through a 5kW pure sine wave inverter all located in the back seat of the trucks. We ran 4/0 SGX cable rated at 120C from one alternator to the other, then from the driver-side alternator to a 400A T-fuse, then to the inverter. Our one way cable run is 18-feet not to include the three feet of cable connecting the two alternators. We ran 4/0 SGX ground cable from the inverter back to the alternator mounting bolt to ensure we have a good ground. We used Burndy 4/0 crimp connectors and a 16-ton hydraulics crimper then shrink wrapped the ends and used black or red split wire loom the entire run, except when passing thru the floorboard. We have triple-checked the wiring and have a good ground with a 0.4VDC total voltage drop over the entire circuit.

So far, power is fine at an 18A load on the AC side at both low and high idle. We are having two issues though. One is that the driver-side alternator is providing most of the power instead of the ECM balancing the load between them. The second issue is the voltage is varying all over the place causing the lights to flicker and the AC blower motor to surge. The truck engine is not surging. Our testing system uses Pulse Width Modulation (PWM) to maintain certain levels of heat in our test system. PWM controls a solid state relay that turns on/off in the millisecond range to control the heating elements. What we have noticed is that the voltage is hopping all over the place from 12.6VDC to 14.2VDC as the PWM controller pulses the electrical demand to the 5 heating units. It has to be the PWM as when the system is at full power heating up the various devices, there is no voltage variation and no surging. The voltage fluctuation continues from the batteries even when we shut off the truck, so it isn't the alternators.

We took the truck to the Ram dealer electrician who said there is no reason for the truck to be doing this. He has built a lot of snow plow and ambulance trucks without these problems. He rewired the truck so the 4/0 cable was attached directly to the batteries instead of the alternator with no improvement. He opened a case to get a Ram engineer to weigh in and said it would be 2-3 days before we would get any info, but 2 hours later he received a response that the truck is fine and it must be our equipment. Pretty much a blow off answer and the dealer isn't happy, but not much they can do I guess. The electrician did say that Ram alternators, unlike Duramax and Ford, do not have a voltage regulator and that the ECM manages it for the entire system.

Our current plan is to run 4/0 cable from each alternator directly to the T-400 fuse and see if this will solve the load balance problem. Based on the results of that, we will then look at an external voltage regulator. We are also looking at options other than PWM for temperature control of our equipment, but that won't fix the load balancing problem.

I have attached our current install diagram. The smaller red lines are the OEM 2-gauge wire and the larger ones are 4/0. I did not include the OEM ground wires. I also included a photo of the wiring in the engine compartment.

We would appreciate any thoughts, ideas, or SWAGs since Ram is no help.

Scott