@gprguy have you put any thought into tires yet? Any plans there?

I have, but the short term plan is run what I've got and wear them down for a while (Hankook DH35). In general I plan to stay with duals, I have no interest in super single rears with the heavy towing. If someone would come out with a super front that matches the height of a good set of duals for the rear (like big dump trucks, wreckers, cement mixers run - but for 19.5's) I'd be all over that.

My original truck was ordered with the off-road tires (Michelin XDS2) and 4.44 gears. The truck I ended up with has the Hankooks and 4.10s. It cruises amazing, but I need to get some towing time before I decide if I can go up to a 245 or something. I doubt I'll want to go to a 265.

When I wear these out I'll figure out if I want to go a size larger and probably do either the XDS2 or maybe the Toyo M608.

I'm also hoping I can carry two spares, and staying with the smaller tires helps with finding space to do that.

General update - last few days have been busy with other stuff, but we went wheeling again while the weather was beautiful.

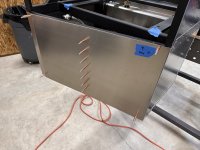

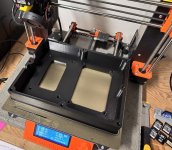

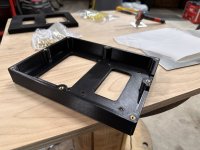

I made two more easy panels.

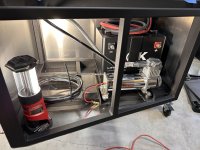

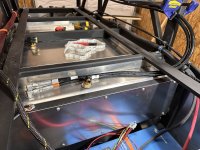

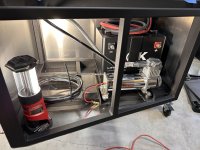

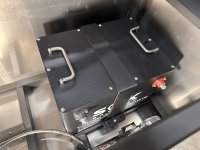

And then decided before I box things in entirely, I should do a little bit of wiring/plumbing while I have better access. So I've started on that. Here's the start of the disconnect and fuse for the big battery to the inverter.

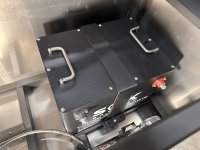

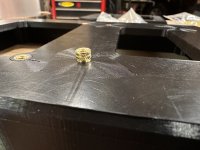

Still working on finishing mounting that, ran out of rivnuts. I also lined the battery tray and strap with some self adhesive rubber strips.

And test fit the battery. It'll come out again, but I am hoping to power up the inverter and test things out before the box goes on the truck.

Just need to finish some wiring and once my shunt arrives I can power it up.

Beyond that, just ordering a lot of odds and ends like air and hydraulic fittings. The more of this stuff I can get at least through the skin of the box before it gets dropped on the frame the easier it will be.