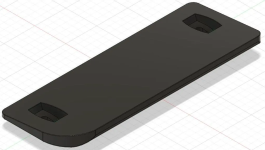

Tried installing the 67 designs plug and play rail. Used their screws, hand tightened. I’m not a total doofas and have been wrenching for 30 years.

Right side radio fastener decided to just spin and wouldn’t come out. Wound up rounding out its hole. I’m miffed how this happened.

Ideas?

This is a 2023 truck with the 12in radio.

Right side radio fastener decided to just spin and wouldn’t come out. Wound up rounding out its hole. I’m miffed how this happened.

Ideas?

This is a 2023 truck with the 12in radio.