Second spring I started with the clamps already on. Removed the center pin nut, and backed off the clamps a little bit on each side at a time until the pack was loose.

Disassembled a layer at a time and laid them out in order. Popped out the old pads, put in the new ones.

Cleaned up the threads, had this second leaf pack done in about 10-15 minutes.

Next challenge was "Man, where the heck do I put these jack stands to get the truck high enough in the back?

As the truck transitions from cab to bed, the frame gets a lot higher. I found that right in front of the front spring hangers was the best spot.

The metal is doubled-up, and they are still far enough back that it's not a see-saw.

At this point I went around and took pictures of all the bolts I'd be removing, to make sure they went back in the same way.

THE MOST IMPORTANT IS THE BOLT CONNECTING THE SPRING HANGER TO THE REAR SPRING EYE!

You get this in backwards, you're pulling the spring back out of the truck to flip the bolt around.

The driver's side top shock mount nut is a pretty tight reach with the spare tire in the way.

I saw no reason to keep that tire up there any longer, since I'll have 37s on there.

Tools to lower the spare are under the passenger's seat. Tons of room with that gone.

Vent hose can get tight, easy to pop that off the axle housing. Just don't forget to push it back on.

Honestly the worst part about this whole ordeal was removing the parking brake cable off the driver's side.

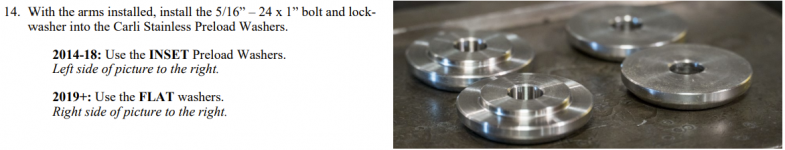

The reason I struggled was I didn't want to mess with the parking brake adjuster. I wasted an hour but finally got it off.

Putting it back on, I wasted another hour, busted knuckles, curse words, and selling myself to the Devil, but still couldn't get it.

Just do yourself a favor, grab the 1/2" wrench, and loosen this this thing way out to get that cable disconnected.

I first marked the backside with white paint so I knew where to tighten it back to.

I've had this tool for many years, it's helpful in pushing on a spring to open things up a bit.

Loosen the adjuster far enough, might be able to muscle it. Nice to have though.

First you've got to push all the prongs in and work the clip out of the bracket.

Then you have to push the spring towards the rear (left in photo) in order to expose the bare parking brake cable so that it fits out the slot.

The spring is a tough one, you can see how it tapers down and actually fits into the end of the clip.

Lots of pressure if you don't relieve it through the adjuster.

Before I started pulling the springs out, I used a couple moving blankets to lay over the bedsides "just in case" a spring wanted to flop in one direction or the other.

Thankfully it didn't, but they are heavy and awkward. But after having one topple in the garage, I was nervous.

I would say it's a two-person job. I'm sure there are people who can creatively get them done alone, but, grab someone else if you can.

Taking the leafs out is easy.

I don't really have any pictures of the removal and installation process.

It was cold, raining, and didn't want to keep the neighbor out there any more than I needed to.

Process basically went like this, NOTE, this is NOT a substitute for following along with the Carli instructions that are provided.

Disassembled a layer at a time and laid them out in order. Popped out the old pads, put in the new ones.

Cleaned up the threads, had this second leaf pack done in about 10-15 minutes.

Next challenge was "Man, where the heck do I put these jack stands to get the truck high enough in the back?

As the truck transitions from cab to bed, the frame gets a lot higher. I found that right in front of the front spring hangers was the best spot.

The metal is doubled-up, and they are still far enough back that it's not a see-saw.

At this point I went around and took pictures of all the bolts I'd be removing, to make sure they went back in the same way.

THE MOST IMPORTANT IS THE BOLT CONNECTING THE SPRING HANGER TO THE REAR SPRING EYE!

You get this in backwards, you're pulling the spring back out of the truck to flip the bolt around.

The driver's side top shock mount nut is a pretty tight reach with the spare tire in the way.

I saw no reason to keep that tire up there any longer, since I'll have 37s on there.

Tools to lower the spare are under the passenger's seat. Tons of room with that gone.

Vent hose can get tight, easy to pop that off the axle housing. Just don't forget to push it back on.

Honestly the worst part about this whole ordeal was removing the parking brake cable off the driver's side.

The reason I struggled was I didn't want to mess with the parking brake adjuster. I wasted an hour but finally got it off.

Putting it back on, I wasted another hour, busted knuckles, curse words, and selling myself to the Devil, but still couldn't get it.

Just do yourself a favor, grab the 1/2" wrench, and loosen this this thing way out to get that cable disconnected.

I first marked the backside with white paint so I knew where to tighten it back to.

I've had this tool for many years, it's helpful in pushing on a spring to open things up a bit.

Loosen the adjuster far enough, might be able to muscle it. Nice to have though.

First you've got to push all the prongs in and work the clip out of the bracket.

Then you have to push the spring towards the rear (left in photo) in order to expose the bare parking brake cable so that it fits out the slot.

The spring is a tough one, you can see how it tapers down and actually fits into the end of the clip.

Lots of pressure if you don't relieve it through the adjuster.

Before I started pulling the springs out, I used a couple moving blankets to lay over the bedsides "just in case" a spring wanted to flop in one direction or the other.

Thankfully it didn't, but they are heavy and awkward. But after having one topple in the garage, I was nervous.

I would say it's a two-person job. I'm sure there are people who can creatively get them done alone, but, grab someone else if you can.

Taking the leafs out is easy.

I don't really have any pictures of the removal and installation process.

It was cold, raining, and didn't want to keep the neighbor out there any more than I needed to.

Process basically went like this, NOTE, this is NOT a substitute for following along with the Carli instructions that are provided.

- Remove the shocks

- Support the axle w/ a jack, remove the U-bolts on driver's side, lower axle to clear center pin

- Loosen the front bolt to drop the captive nut, don't remove bolt

- Beware this is 30MM, not part of most sets

- Loosen the rear lower bolt to drop that captive nut, don't remove bolt

- The spring hanger comes out attached to the rear of the spring, no need to mess with that one

- Cargo strap around the spring toward the front side of the axle, attached to the frame. There's places to hook onto

- Remove rear hanger bolt

- Remove front hanger bolt

- Work with your partner to loosen cargo strap, then slide the spring out from under the truck toward the front

- Spring hanger may interfere with removal, use breaker bar to turn hanger-spring nut to straighten that hanger out a bit to get some clearance

- This happened to me on passenger side

- I put old spring next to new spring, upside-down to transfer hanger

- Bolt head is T-60 TORX or I guess Vice Grips if you don't have the right tool

- MAKE SURE BOLT IS EXACT SAME DIRECTION or you'll be pulling it back out

- Hand-tight, final tightness done after installation

- Loosened passenger side U-bolts to allow axle to drop far enough to get new taller spring in

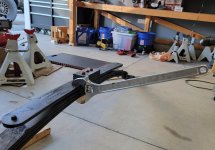

- Used my fancy dolly to roll it out to the truck

- Worked it up on top of the axle, cargo strapped back in place

- Rear bolt installed snug

- Front bolt installed snug

- Use that big 24" adjustable wrench on the spring to get it to "twist" as necessary to line up bolt holes as needed

- Jack axle back up slowly to spring pack, make sure centering pin is in correct location

- U-bolts are a bit long, even for a deep socket

- Had to cut U-bolts down a bit once I got them installed to get them fully tightened

- Do it all again on the passenger's side

- Hanger bracket was too tall to slide spring forward, had to turn nut to allow bracket to turn more horizontal

- Re-route parking brake cable. Going to use a little muscle and feel a bit awkward pulling it through the frame

- Attach it to spring pack using P-clamp

- Attach that damn parking brake cable back to the parking brake using whatever prayers necessary

- Tighten adjuster back to where it was

- When going through torque sequence (follow instructions), need impact wrench to tighten hanger-to-spring nut

- Regular ratchet just spins TORX-head bolt, no way to stop it from spinning

- Air impact is very cramped inside bedsides with the air couplings hitting everything, electric would shine here

- Install rear shocks