Truck is a 2021 RAM 3500 without the air system. I ordered the base Backcountry kit along with their torsion sway bar and full progressive leaf springs.

To head off a couple questions I get asked:

"Why didn't you just get a 2500?"

I didn't want rear coils.

"Why are you going to "waste" a 3500 by putting such low capacity rear leaf springs on?"

I don't tow heavy nor load my bed heavy. If I do end up some day needing that extra capacity, I can always add airbags later.

Previous install experience has been a Thuren system on my old '07 RAM 2500, and a Carli Backcountry system on my wife's Wrangler. This install looks a bit more involved, but, hopefully nothing too drastic. No welding is required thankfully.

I wish I had a huge garage and a lift installed. Or even a normal sized garage that would fit the truck inside. My garage is 20' deep, so I'm stuck outside.

I'll be posting a lot of pictures and explaining some things along the way that may hopefully help others out in the future when they do their systems.

Sway bar drop is because I was going to run the factory sway bar while waiting for production to finish on the Carli sway bar.

The Carli bar came in before I got around to installing the system, so now I'll have to sell that or something.

I have almost 30K miles on the truck now. First time up in the air.

(Yeah, I didn't rotate the factory tires, just going to get rid of the wheels/tires anyways once I get these new ones on.)

I used the jack under the radius arm/axle connection area of each side to lift the truck.

The diff looked a bit too far off-center to try using that.

Rear wheels chocked.

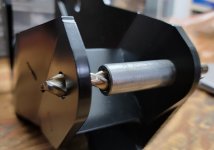

First part to install is the Radius Arm Drop Brackets.

This is the most intimidating part to me as it requires drilling the frame. One drilled hole per bracket.

I've never done brackets. (Fear not, Carli makes it super simple, to be detailed later.)

Hell of a packing job with them as well.

The bolts are conveniently divided up into four sections for the different uses.

Not labeled, but, easy enough to figure out which section is what using a tape measure and the contents inventory.

To head off a couple questions I get asked:

"Why didn't you just get a 2500?"

I didn't want rear coils.

"Why are you going to "waste" a 3500 by putting such low capacity rear leaf springs on?"

I don't tow heavy nor load my bed heavy. If I do end up some day needing that extra capacity, I can always add airbags later.

Previous install experience has been a Thuren system on my old '07 RAM 2500, and a Carli Backcountry system on my wife's Wrangler. This install looks a bit more involved, but, hopefully nothing too drastic. No welding is required thankfully.

I wish I had a huge garage and a lift installed. Or even a normal sized garage that would fit the truck inside. My garage is 20' deep, so I'm stuck outside.

I'll be posting a lot of pictures and explaining some things along the way that may hopefully help others out in the future when they do their systems.

Sway bar drop is because I was going to run the factory sway bar while waiting for production to finish on the Carli sway bar.

The Carli bar came in before I got around to installing the system, so now I'll have to sell that or something.

I have almost 30K miles on the truck now. First time up in the air.

(Yeah, I didn't rotate the factory tires, just going to get rid of the wheels/tires anyways once I get these new ones on.)

I used the jack under the radius arm/axle connection area of each side to lift the truck.

The diff looked a bit too far off-center to try using that.

Rear wheels chocked.

First part to install is the Radius Arm Drop Brackets.

This is the most intimidating part to me as it requires drilling the frame. One drilled hole per bracket.

I've never done brackets. (Fear not, Carli makes it super simple, to be detailed later.)

Hell of a packing job with them as well.

The bolts are conveniently divided up into four sections for the different uses.

Not labeled, but, easy enough to figure out which section is what using a tape measure and the contents inventory.