Frame mounted sliders are too heavy and annoying to install to be something you take on and off, so if that is even a consideration, I'd give up on that right now. Additionally, anything that would make them easier to install/remove is likely going to limit their strength, and thus probably not something easily made. You could probably find someone to make or modify a "sleeve" version, where the sliders slide into the frame mounts similar to a hitch mount, but again, they are heavy and wide so it would be a bit of a process getting them on/off, and I'm not sure about interference with the AMP steps while installed, so you may need to make them low enough to clear even while the AMP steps are retracted.

Randy Ellis Designs has some body mounted sliders that work well with the AMPs, and they are very strong, but the downside is that it's a pretty permanent install requiring you to drill dozens of rivnuts into the body to mount it. If you live in an area with rust, you should take care to make sure everything is painted and sealed as well as it can be or you're risking fighting rust.

There is a company that makes sliders that have a retractable drop down step similar to the AMPs, but to my knowledge it's only for Jeeps and a few toyotas. There was a company that made them for Rams, but they either no longer do or went out of business as I've not found them.

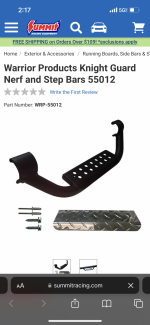

Functionally, I think something like a frame mounted "slider" with an internal step that drops down would be a great option, but they would be complex to manufacture on a 1 off basis I think, and with the cost, I'm not sure how well they would sell as a business. I've been thinking about doing this for my truck for quite some time. I think it would be possible to weld together metal plate into a triangle, and then cut out one of the sides and building a step, so that it looked semi-flush while retracted, then then operates by "scissoring out" rather than dropping straight down. Basically something like

Rock Slide Engineering but frame mounted. Is it possible? Probably, but not very cost effective.